Discover how ACCURL’s press brakes can help you optimize your production

Accurl offers productive CNC hydraulic press brakes, new customized solutions, and easy-to-use option suites designed to meet the customers real needs and provide them with the right machine for their businesses.

ACCURL hydraulic CNC press brakes are fully configurable to customer needs. Our green hybrid servo and electric servo bending technology for sheet metal has made ACCURL a Top 10 press brake manufacturer in China, with a substantial technological edge over competitors.

ACCURL press brakes are designed for power, productivity, and versatility. Our machinery’s robust construction and advanced technology ensures dependable operation and flawless repeatability, managing materials from soft brass to chrome molybdenum.

Our press brakes range in size from 35 tons to 6000 tons (in tandem) and bed lengths from 0.8m to 24m (in tandem). They come in a variety of configurations from 2 to 11 axis.

With the ability to handle diverse requirements, ACCURL boosts productivity while maintaining unwavering reliability. The precision our press brakes deliver is a testament to our commitment to innovation and superior craftsmanship.

A consolidated technological background and inventiveness are what drives ACCURL. ACCURL is one of the first companies to apply Industry 4.0 in the world of sheet metal bending machines in China.

ACCURL Smart Economic 3-4 Axis

Simple Press Brake Machine For Sheet Bending

The ACCURL® Press Brake Smart 3-4 Axis Series is a small CNC press brake bending machine with impressive features that delivers high-pressure bending capacity. Benefit from advanced DELEM DA53T 2D capable controls or Cybelec CybTouch 8PS.

Choose ESA S630 or ESA S640W CNC control systems. ACCURL Smart Series is your first choice in Y1/Y2 machine technology at a competitive price – include all standard features and is ideal for smaller production workshops!

ACCURL Euro Pro Series 4-6 axis

CNC Press Brake Machine For More Demanding Tasks

The ACCURL® New EURO PRO Series CNC press brake features high-quality build, 2.5-6 meter bending length, and 50-400 tons of bending force.

With advanced DELEM DA66T or Cybelec CybTouch 15PS 2D capable controls, the Euro Pro Series handles all 4-6 axis sheet metal forming needs.

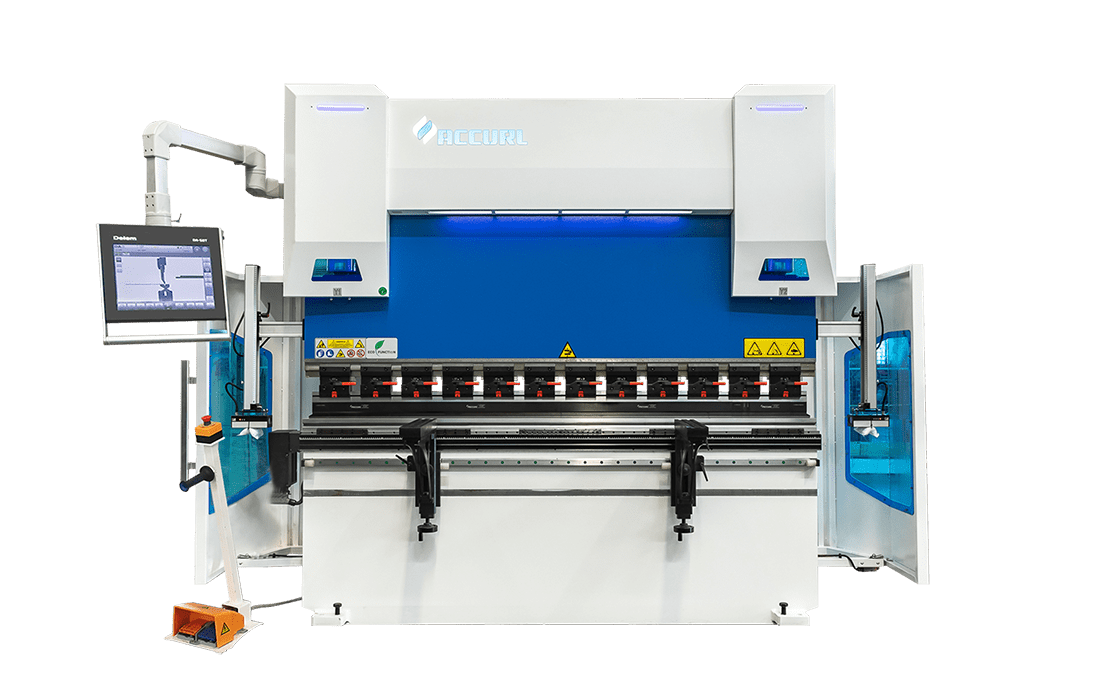

ACCURL Genius Plus Series 6-8 axis

CNC Press Brakes For Quiet Operation, Large Daylight & Stroke

The ACCURL® New Genius Series Hybrid servo CNC press brakes are based on the proven design of our Pro Series. It features increased efficiency, faster bend speeds, stroke, and greater pressing capacity.

Benefit from 50% more energy savings than using a CNC hydraulic press brake. With advanced motion technologies and impressively quiet operation, the Genius Plus Series is the ultimate choice for creating complex parts.

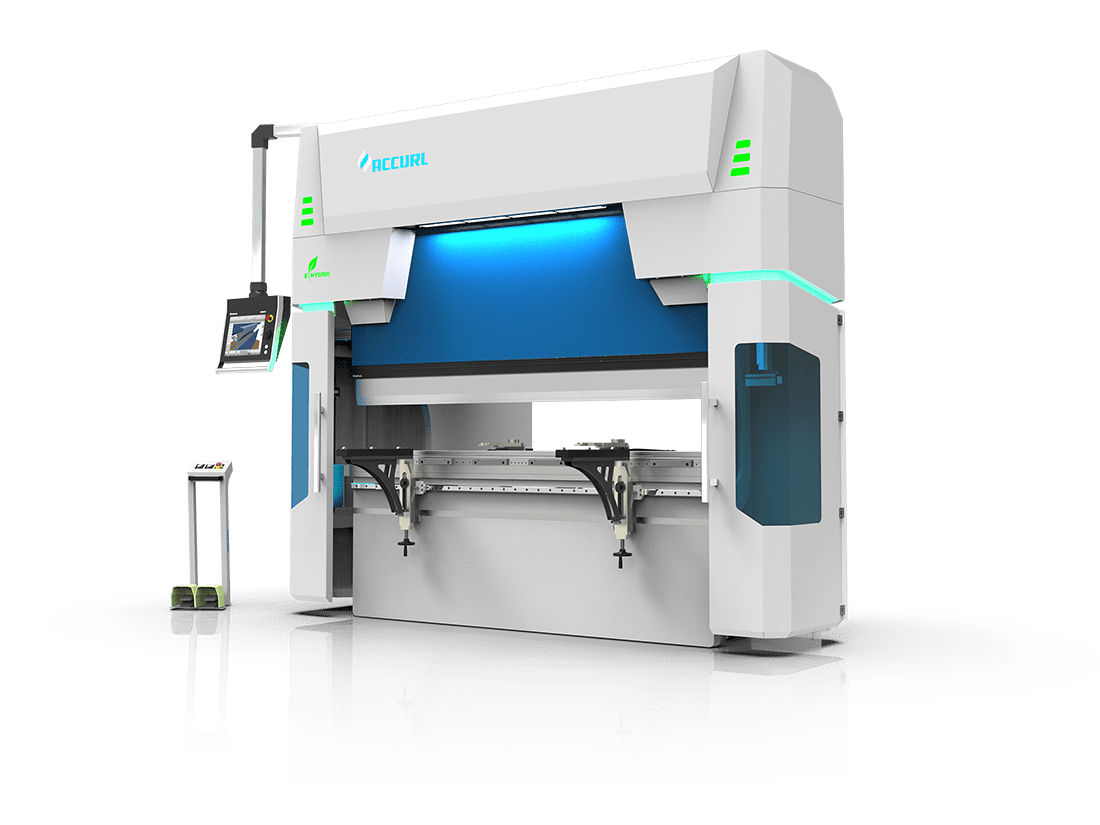

ACCURL Electric Press Brake eB Icon Servo

100% Electric Bending Technology!

The eB-Electric Press Brake from ACCURL features the advantages of fast acceleration and deceleration, and rapid response time of the ball screw servo drive system. Plus, it eliminates the need for hydraulic oil and reduces energy consumption by 50%.

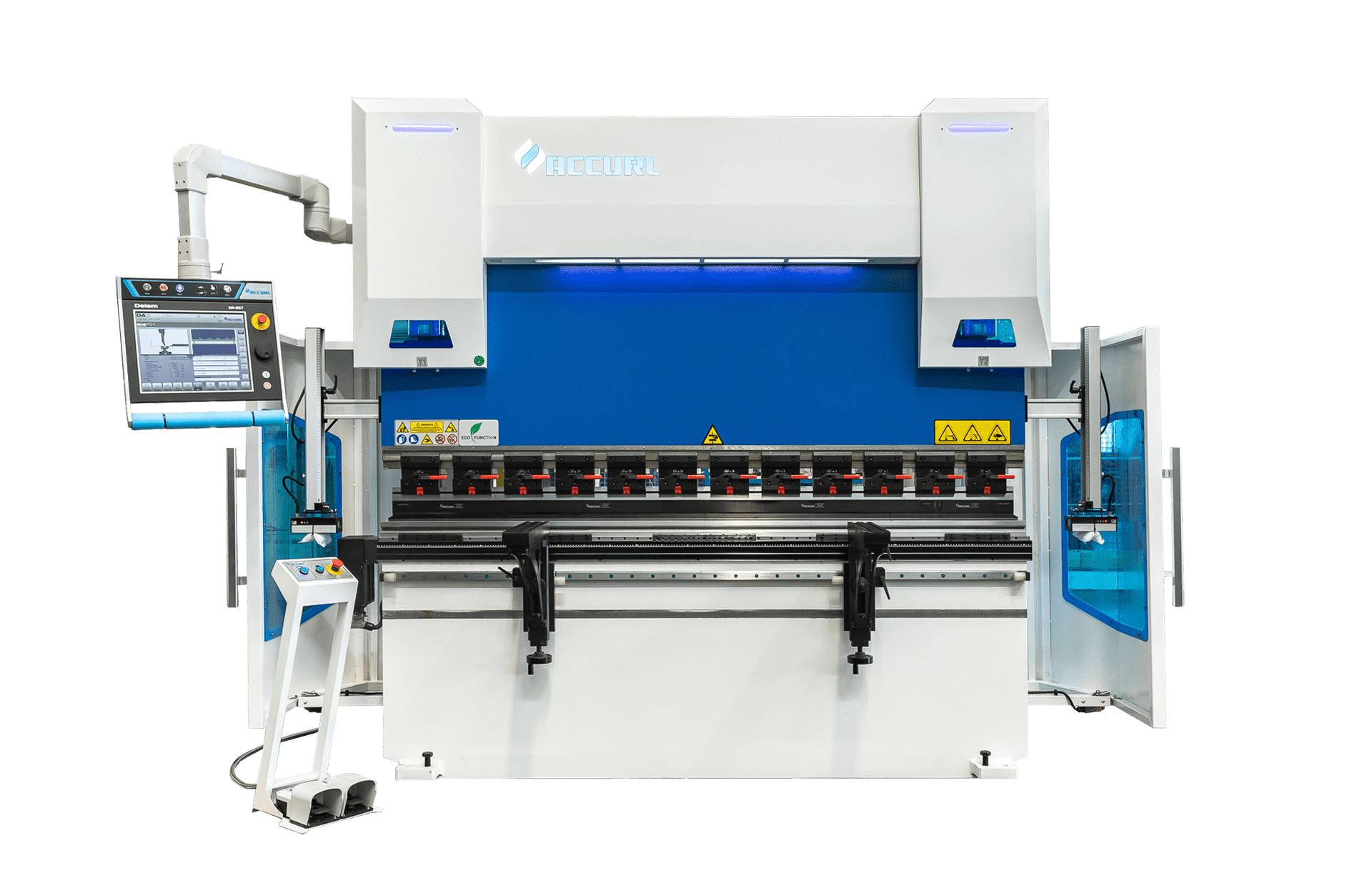

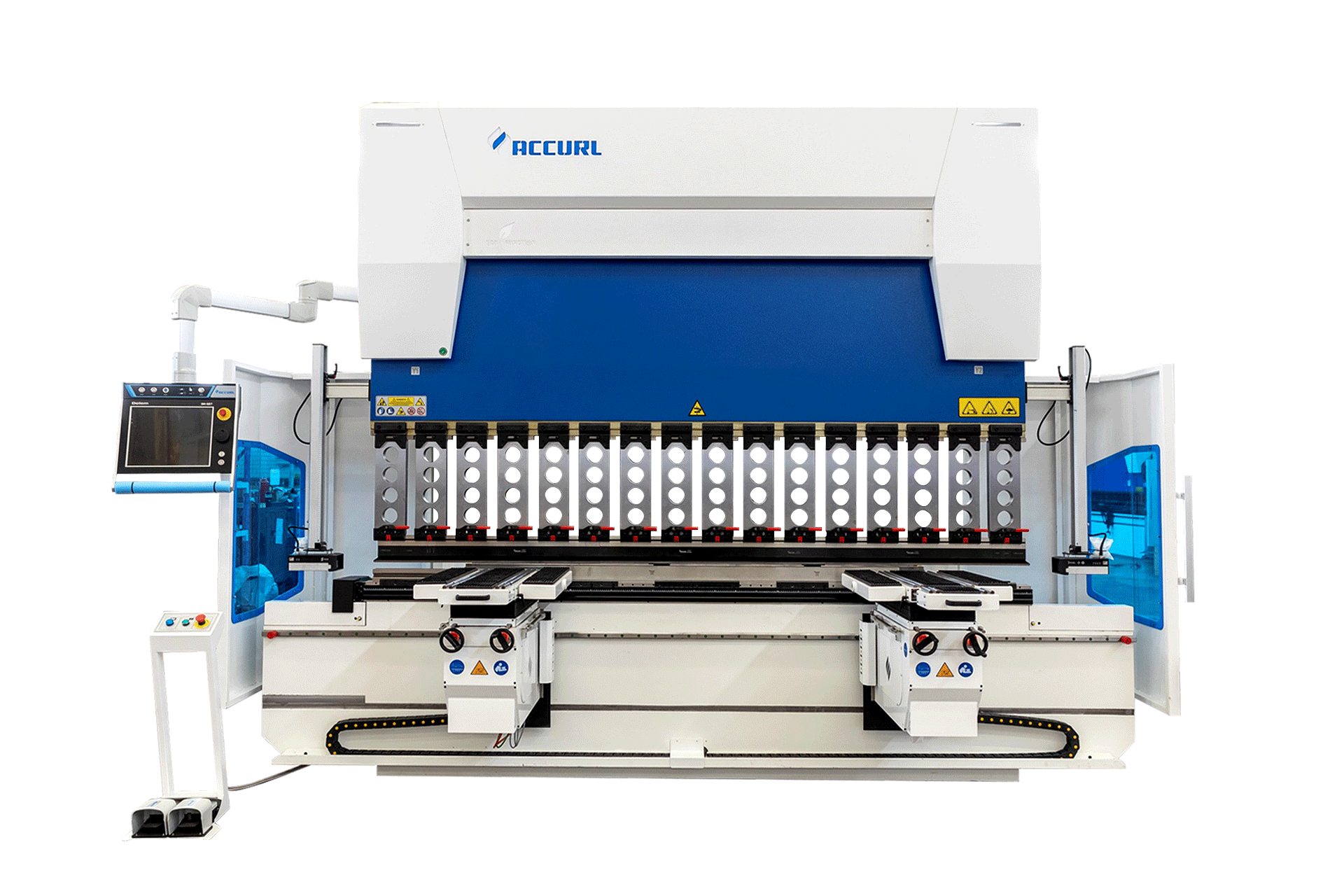

ACCURL Top Custom Press Brake!

Super Custom CNC Press Brakes | Deep-Box Bending Solution

The ACCURL® Super Custom Press Brake GENIUS CNC machine is fully configurable with extended stroke and large daylight to make deep-box bends in electrical appliance manufacturing easier!

Can bend boxes up to 800mm deep with the utmost accuracy and without need for special tooling.

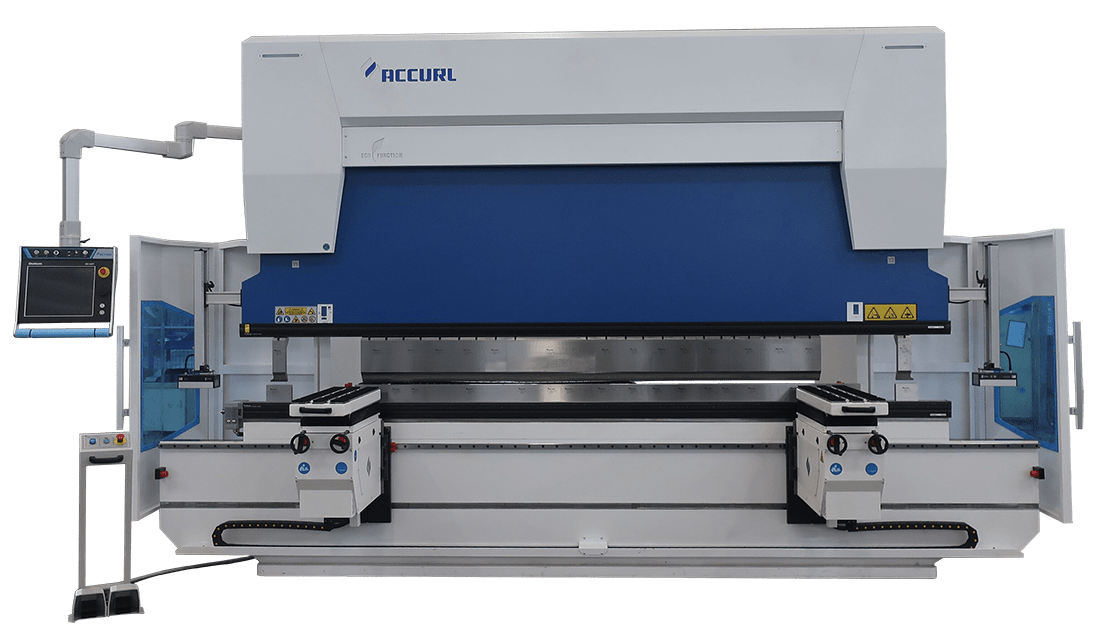

ACCURL EuroMaster Hybrid Press Brake

The Best Professional Bending Solution

The ACCURL® EuroMaster hybrid press brake is built with high-end specifications, precision execution, and advanced motion technologies. But is still impressively quiet!

With the integration of advanced safety features and options, the EuroMaster press brake machine is the best option for creating complex parts.

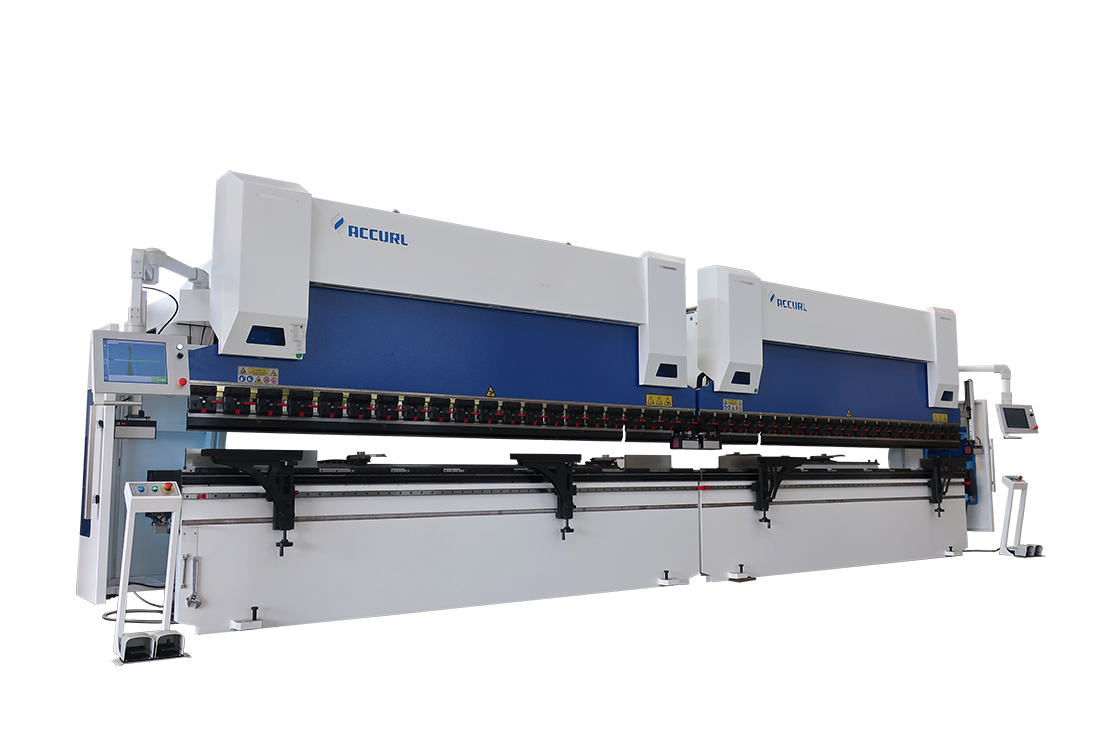

ACCURL Tandem Press Brake

Tandem Press Brakes for Sheet Bending

ACCURL Tandem CNC Press brakes are equipped with CE Lazersafe LZS-XL. Switch between tandem or single-mode operation at any time. All working modes comply with the strictest CE standard. Uses 50% less energy than a conventional hydraulic press brakes.

Two hydraulic press brakes may be used in tandem to increase the efficiency of bending large lengths or independently for creating smaller bends.

Various features include fast switching between simultaneous or stand-alone modes, and super safe Lazersafe adapter technology

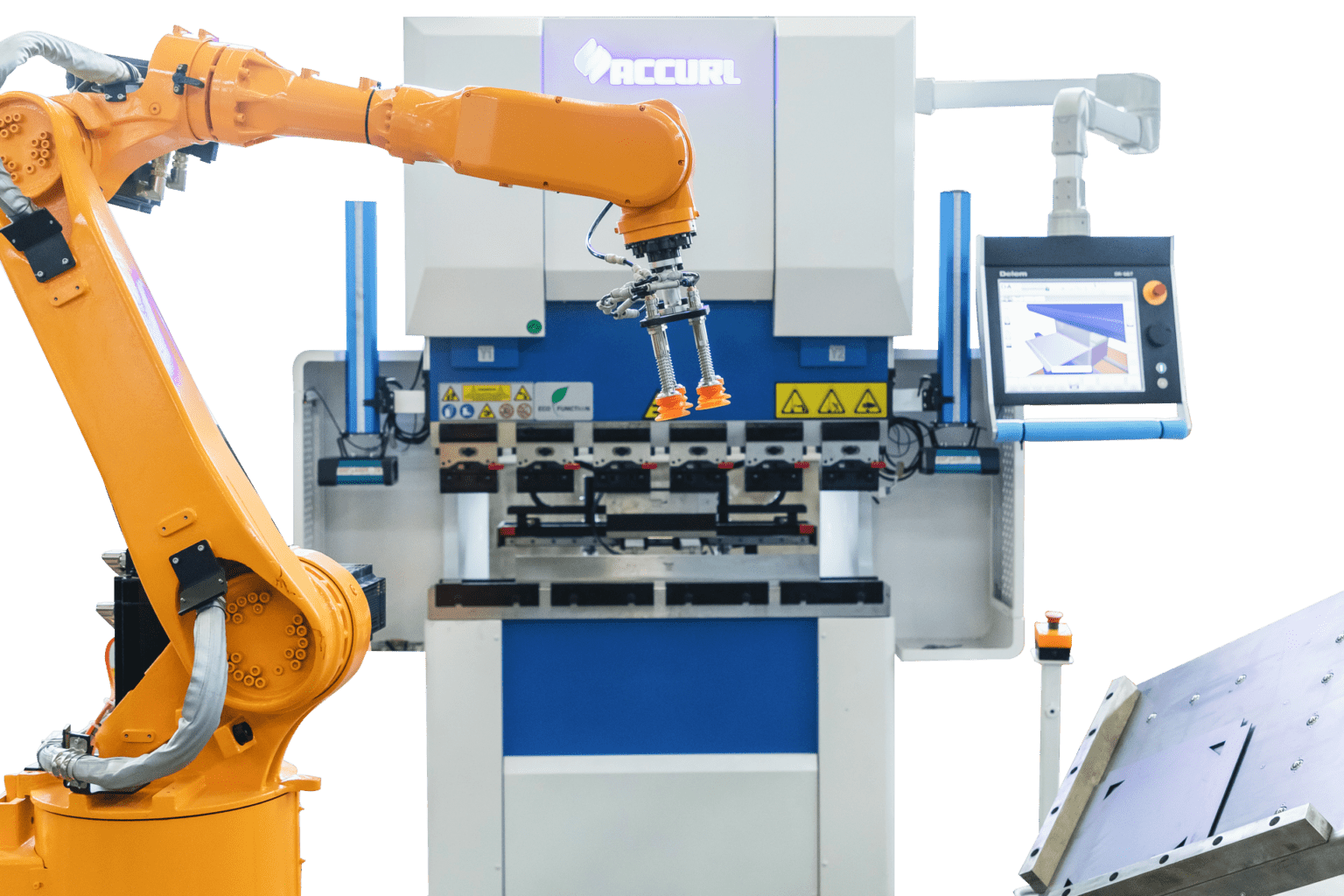

ACCURL Press Brake Bending Robotic Cell

ROBOformAI - The Professional Robotic Bending Solution

ACCURL’s ROBOformAI bending robot and automatic loading/unloading devices provide a reliable solution for automated production. Multiple configurable loading/handling options to meet customer needs. Increased safety through zero operator risk during sheet metal bending operations make ROBOformAI the perfect machine for the job.

Why ACCURL Press Brakes?

Innovative Modular Design:

Our hydraulic press brakes can also be combined with automation modules to create a complete hydraulic system for the whole working process and further improve the versatility of the machine.

Customized solutions at a reasonable price, from basic to high end machine. Check our press brakes for sale, for more varied configurations and technical parameters.

Experience

33 years of experience and more than 12,000 installed machines.

An expert R&D team committed to research cutting edge technologies for the press brakes of our customers.

More Varied Solutions for Bending:

Sustainability and social responsibility are characteristics of modern companies and add to competitiveness.

Comprehensive range of basic tools in stock and modified solutions according to customer needs

ACCURL high quality equipment:

The critical parts of the Accurl press brakes are manufactured in Germany.

We rely on our quality and therefore give our hydraulic press brakes a 5-year warranty.

The HOERBIGER hybrid system is an innovative servo drive for press brakes.

After-Sales Service & Support:

Original ACCURL spare parts to guarantee full performance and prolonged durability.

Wide range of consultation services on machine operation,programming and maintenance.

FAQs

What is a press brake machine?

A press brake is a computer-controlled machine tool used to shape and form sheet metal. It consists of two parts: the ram, which moves up and down to bend the metal part, and the bed, which holds the workpiece material in place. CNC controls produce consistent precise bends faster and easier than non-CNC press brakes.

What are the benefits of using ACCURL CNC press brakes for sheet metal bending?

The main benefits of ACCURL press brakes are increased accuracy, enhanced flexibility, speed, cost savings, and safety. With a CNC-controlled machine, the operator does not have to manually measure and mark where to make bends in the sheet metal.

Accurl offers productive CNC press brakes, new customized solutions, and easy-to-use option suites designed to meet the customer’s real needs.